-

Hot-selling High Gloss Non Crust Ink - Curing Agent for printing inks – VTEX GROUP

Curing Agent for printing inks 1. ECO approved. 2. Can add 5% with inks and mixed to make more good wash ability. 3. Can be used with other brand inks. -

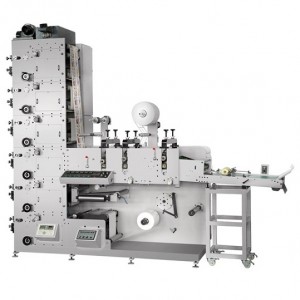

Adhesive Printer Flexo Printing Machine - New Style Flexo Printing Machine – VTEX GROUP

Precision of multicolor flexo label printing machine Developed from old style flexo machine, which not only inherit excellent characters of previous series, but also design a new function of non-stop register and pneumatic clamping mechanism, making printer easier operation, more excellent color, more stable printing quality and higher efficiency. Technical Parameter Model Printing Color Total Power Weight (L*W*H) MM XHRQ-21 2+1 6KW 800KGS 1835X946X1680 XHRQ-41 ... -

Factory Cheap Hot Eco Wax Ribbon - Eco Wax Ribbon – VTEX GROUP

Eco Wax Ribbon offers our most economical thermal transfer printing solution while providing consistent performance on a wide variety of materials. Designed for barcode label and tag printing in the mainstream”sweet-spot”of 4-8 inches per second, provids high optical density,moderate image durability,and allows printing at low print head energy heat settings on all popular thermal transfer printers. highly versatile ribbon which provides reliable printing performance on coated ... -

Pe Film Flexo Printing Machine - Flexo Label Printing Machine – VTEX GROUP

XHR Series Flexo Label Printing Machine The printing principle of the Flexo Label Printing Machine is to transfer the ink from the high precision anilox roller to plate, then from the plate to the printing materials. It can make stable and high speed printing on cloths, ribbons and paper rolls with the printed result of thick and solid ink layer and good fastness.The plate cylinder of di erent circumferences can be replaced, so that to change the printing length. The machine is equipped wi... -

professional factory for Printing Machine Flexo - IML label Flexo Printing Machine – VTEX GROUP

Flexo Printing Machine for IML Label and Heat Transfer Films Instruction: 1.Printing color: 6-10 colors (Arbitrarily increase or decrease ), for example: 8+0 7+1 6+2 5+3 4+4 2.Max. Mechanical Speed: 130m/min 3.Max. Printing Speed: 120m/min 4.Reticulated Rod: Ceramic Roller 8, closed scraper 8 sets 5.Accuracy of Registration: vertical ±0.25 mm( manual operation) 6.Broad wise: ±0.15 mm(manual operation) 7.Max. Diameter of Roll Material: Φ800 mm 8.Ai... -

Factory directly supply Offset Machine - Flexo Label Printing Machine – VTEX GROUP

XHR Series Flexo Label Printing Machine The printing principle of the Flexo Label Printing Machine is to transfer the ink from the high precision anilox roller to plate, then from the plate to the printing materials. It can make stable and high speed printing on cloths, ribbons and paper rolls with the printed result of thick and solid ink layer and good fastness.The plate cylinder of di erent circumferences can be replaced, so that to change the printing length. The machine is equipped wi... -

Food Packaging Printing Ink - Reducing Medium For Flexo Inks – VTEX GROUP

Reducing Medium For Flexo Inks 1. ECO approved. 2. Can make inks more smooth when printing. 3. Need add 10% reducing medium and mixed with inks before using to machine. 4. Can be used with other brand printing inks. -

Rtv2 Silicone Ink - Printing Inks For Flexo Printing Machine – VTEX GROUP

Printing Inks for Flexo Printing Machine 1. ECO Approved 2. EN-71-3 Approved 3. ROHS approved 4. Dehp Approved Characteristic 1. Green and Eco passed, less smell, colorful good tinting, anti-wash, anti-rub, anti-color fading. 2. Can be used for all kinds of label fabric, like nylon taffeta, polyester satin, polyester taffeta, acetate taffeta, etc. Physical Need adjust hearter temperature as per anilox roll size, and keep printing speed normal, so inks can more fast to drying. &n... -

China Supplier Pe Foam Tape - Normal Slit Edge Polyester Satin – VTEX GROUP

Normal Slit Edge Polyester Satin 1. For Care Label Printing. 2. Suitable Printing Way: Letter Press, Rotary, Silk Screen, Offset, Thermal Transfer. 3. OEKO certificate. 4. GRS certificate. -

OEM China Trade Mark Tape - Black Polyester Taffeta – VTEX GROUP

Black Polyester Taffeta 1. For Care Label Printing. 2. Suitable Printing Way: Letter Press, Rotary, Silk Screen, Offset, Thermal Transfer. 3. OEKO certificate. 4. GRS certificate. -

Silk Screen Print Machine - Screen Plate Drying Machine – VTEX GROUP

Screen Plate Drying Machine Stainless steel drawer, corrosion-resisting, circulating hot air drying, even temperature distribution, high drying capability. Technical Parameter Style: HB-1400 Max. Frame Size Max. Temperature Voltage Outer size (LxWxH) 800 X 900 (MM) 50℃ 220V/380V 1.0 x 1.2 x 1.5 (M) -

Hot New Products 6 Color Flexo Printing Machine - Flexo Printing Machine With Three Die-cutting Stations – VTEX GROUP

Flexo Printing Machine With Three Die-cutting Stations Main Features 1.Adopt the ceramic anilox cylinder to transfer the ink. 2.Each printing unit adopts 360° plate-adjustment. 3.Three die-cutting stations, the first and second die-cutting station can do double sides working, the third die-cutting station can be used as sheeter. 4.Computerized web-guiding system is installed in the front of printing unit,it ensures the material always in the right position. (standard configuration) 5.After...