China Cheap price Intrared Label Drying Machine - High Speed Rotary Press – VTEX GROUP

China Cheap price Intrared Label Drying Machine - High Speed Rotary Press – VTEX GROUP Detail:

High Speed Rotary Press (Shaftless Plate Fitting)

Main Technical Data

Machine direction From the left to the right

Print colors 6-10 COLORS

Max. Web width 1000 mm

Max. machine speed 150 m/min (¢150mm plate cylinder)

Max. Print speed 130 m/min (¢130mm plate cylinder)

Register accuracy ±0.1㎜(auto adjust system)

Unwind reel dia ¢650㎜

Rewind reel dia ¢650㎜

Tension range 3-30㎏ (full load)

Tension accuracy ±0.3㎏ (breadth accuracy)

Paper core dia ¢76㎜ ×¢92㎜

Air source 0.6 MPa

Doctor dance ±5 ㎜

Drying electricity

Main motor power 11.0 KW

Total machine power 100.00 KW

Overall dimensions 14950㎜ ×2600㎜×2700㎜

Machine weight 11000 KGS

Substrate

PVDC 35~60um

PET 12~60um

OPP 20~60um

BOPP 20~60um

PE 30~100um

NY 12~50um

CPP 20~60um

Combination Film 15~60um

And ther characteristic film

********************************************************************

Unwind Unit

Structure

1. Built-in dual-position rotary turret

2. Double shafts unwind reel independently and actively

3. YASKAWA vector controller is used in the independent transmission system

4. DANCER: Tension detector system and DANCER constant tension system

5. Close-loop tension control

6. Automatic changing reel with alarm system for reminding the worker to change the reel

Specification

1. Max. paper core width 94mm

2. Max. unwind reel ¢600 mm

3. Unwind motor AC4KW+ENCODER+FAN (AC4KW with 4KW vector controller ,YASKAWA)

l Rotary turret Speed 1 r/min

l Tension range 3~30kg

l Tension accuracy ±0.3kg

Features

1. Nonstop changing reel at high efficiency will save your time

2. Synchro. Changing reel, constant tension, low waste

3. Active unwinding is controlled by AC vector motor and completes the little tension control and makes constant output whenever at low aped or high speed

4. Low-friction air cylinder tension detector, tension can be adjusted quickly and exactly.

5. Rotary turret can rotate and locate automatically; it can cancel its performance in the case of emergency

6. Cutter has regular working position, and will be locked at the mode of machine stop

********************************************************************

Infeed Unit

Structure

1. Steel roller to flexible roller

2. The steel roller is the power ,which is driven by independent motor

3. AC2.2KW: The power of steel roller is from YASKAWA AC 2.2kw vector controller

4. Flexible roller up/down and pressure adjustment are completed by pneumatic components

5. High sensitive close tension control

6. Tension DANCER roller joins the close-loop tension control

Specification

1. Steel roller ¢125㎜

2. Flexible roller ¢100㎜

3. Chemigum shore (A)65~70°

4. Tension set 3~30kg

5. Tension accuracy ±0.3kg

6. Drive motor AC2.2KW+ENCONDER+FAN (with AC2.2kw vector controller,YASKAWA)

7. Max. Pressure of flexible roller 300kg

Feature

1. Steel roller to flexible for assuring the section-tension differentiated

2. Close-loop tension control will produce constant print tension

3. Flexible roller up/down links with the main motor, which is completed by central controller

4. Tension control at easy operation links with the main motor

5. Independent unit frame at high accurate installation

********************************************************************

Print Unit

Structure

1. Shiftless cylinder fitting,and lateral installation of the plate cylinders can be adjusted for assuring initial position of them identical.

2. Integral impression roller, easy to change

3. Then impression roller up/down adopts the dancer-arm type,which can assure the minimum web change.

4. Impression rollers are on pressure in sequence and out of pressure at the same time .

5. Open-type,automatic returning ink,manual ink pan up/down

6. Pneumatic doctor up/down,three-dimension doctor adjustment by the big hand wheel

7. Oscillating doctor and oscillating frequency makes proportion with the motor running

8. Powerful gearbox integrates with the pneumatic pressure system; oil immersion gearbox has the seal structure

Specification

1. Cylinder length 650-1000mm

2. Impression roller ¢120 mm ternary rubber (shore(A)75°±2°)

3. Max. Impression 500 kgs

4. Doctor pressure 10-150 kgs

Features

1. Compensation is controlled by the precise ball screw for exact and flexible color register

2. It is equipped with the quick lifter,which can make the impression roller locked at the mode of machine stop

3. Airing the cylinder system will avoid appearing the dirty dot

********************************************************************

Drying Unit

Structure

1. Pneumatic oven open/close along guide rail

2. Independent drying system design for color

3. Intelligent constant temperature control

4. Seal heat preservation oven,heat source can be secondly used

5. Long and flat air nozzles

6. Electric heating

Specification

1. Web length in hood 1400 mm (1600 mm in the eighth color)

2. Air nozzles 7 pcs

3. Air speed 7 m/s

4. Air reused 0-50%

5. Temp. Control accuracy ±2℃

6. Heating power for each unit 18.5 kw

7. Max. oven temperature 80℃ (indoor 20℃)

8. Max. Airing volume 2800 m3/h

9. Blower power 1.1 KW/unit

Features

1. Air reused will save the energy source

2. More air ways make the whole web air cyclone,drying from inside to surface and no bubble produced

3. Automatic constant temperature will benefit each color print

4. Big air flow will make low-temp high-air speed drying

5. Negative pressure is designed inside oven,hot air will not be blown to the surface of the plate cylinder and the cylinder will not be dried and no solvent waste

6. Heating tube can be changed easily

7. Side-lay heating system,the soft hose connects the machine with the heating system for avoiding resonance.

8. Cooling fan 0.55 kw (each unit)

********************************************************************

Outfeed Unit

Structure

1. A steel roller to a flexible roller

2. The steel roller is power roller,which is driven by the independent motor

3. YASKAWA vector controller system is used in the independent transmission components

4. High sensitive close-loop tension control system

5. Tension dance roller joins the close-loop control and reaction signals are sent by the linear potentiometer

Specification

1. Steel roll ¢125mm

2. Flexible roller ¢120mm (chemigum shore (A)65~70°)

3. Tension set 3~30kg

4. Tension accuracy ±0.3kg

5. Drive motor AC2.2KW+ENCONDER+FAN (with AC2.2kw ,YASKAWA vector controller)

Feature

1. A Steel roller to a flexible roller for assuring tension section differentiated

2. Independent close-loop tension control will produce constant print tension

3. Tension control at easy operation links with the main motor

4. Independent unit-frame at high accurate installation

********************************************************************

Rewind Unit

Structure

1. Built-in dual-position rotary turret

2. Double shafts rewind independently and actively

3. YASKAWA vector controller is used in the independent transmission system

4. Tension detection system and a set of DANCER system for stable tension

5. Close-loop tension control

6. Rotary turret can rotate,change position and locate automatically

7. Tension and tension attenuation can be set freely in Chinese on the Human-Machine Interface

Specification

1. Max. Paper core width 1050mm

2. Max. Reel dia. ¢600mm

3. Rewind motor AC4KW+ENCODER+FAN (YASKAWA 4KW vector controller)

4. Rewind tension attenuation 0~100%

5. Rotary turret speed 1 r/min

6. Tension range 3~30kg

7. Tension accuracy ±0.3kg

Feature

1. None-stop changing reel at high efficiency and time saving

2. Synchro changing reel at constant tension,low waste

3. AC motor controls rewinding,completes zero tension control,and makes constant output whenever at low speed or high speed

4. Low-friction air cylinder is used for tension or high speed

5. Rotary turret can rotate and locate automatically

6. Cutter has the regular working position and can be locked at the mode of machine stop

7. Tension attenuation function can guarantee the degree of tightness in reel’s outside identical and no core appearance

********************************************************************

Rack And Web Travel

Structure

1. Frame at high-strength low-stress is made of alloy cast iron

Specification

1. Side-frame thickness 70 mm

2. Distance between two units 1-1.4m

3. Guide rollers ¢70 mm ¢80 mm ¢100 mm (dynamic balance up to grade 2.5 and static balance up to 2 g)

4. Guide roller length 1050 mm

5. Thread step of the guide roller 30 mm

Feature

1. All frames are twice internal-stress eliminated for guaranteeing machine running stable

2. Precise frames are processed by imported priority for guaranteeing accurate location

3. Guide rollers are well arranged to guarantee web running balance

********************************************************************

Main Transmission Unit

Structure

1. The main motor transmits power to each unit via a common shaft

2. Connecting the gearbox and other junctions flexibility

3. The main motor has independent bottom plate and reduction gear

Specification

1. Motor power AC11KW+ENCODER+FAN (with YASKAWA 11KW vector controller)

Feature

1. Low-speed full-load start up

2. Automatic acceleration

3. The main transmission and other motors are integrally controlled and act in step with the whole machine

********************************************************************

Tension Control

1. Four-section at coordination control

2. High accurate tension control,acceleration/deceleration will not affect tension

********************************************************************

Lighting System

LED

********************************************************************

Computer Tracking System

Model:Wuhan Brand

********************************************************************

Air Duct System

Water removers and filters mounted on each unit and centralized point of pneumatic components

********************************************************************

Anti-Static System

Static Brush

********************************************************************

Machine Attachments

Tool kits 1 set

Web inspection video system (Wuhan) 1 set

********************************************************************

Machine Main Parts Brand

1. Tension control system Japan

2. PLC Panasonic,Japan

3. Unwind motor AC4KW+ENCODER+FAN (ABB) (with YASKAWA 4KW vector controller)

4. Main motor AC11KW+ENCODER+FAN(ABB) (with YASKAWA 11KW vector controller)

5. Rewind motor AC4KW+ENCODER+FAN(ABB) (with YASKAWA 4KW vector controller)

6. Infeed motor AC2.2KW+ENCODER+FAN (with YASKAWA 2.2KW vector controller)

7. Outfeed motor AC2.2KW+ENCODER+FAN (with YASKAWA 2.2KW vector controller)

8. Human-Machine interface Weilun,Taiwan

9. Low-friction air cylinder Fuji Kura,Japan

10. Precision air vent valve CKD

11. Main pneumatic components Airtac

12. Main bearings American

13. Guide roller ¢70mm ¢80mm ¢100mm

14. Low-voltage components Schneider

********************************************************************

Remarks

The machine is the hi-tech product,we reserve the right to alter the parameters and machine structure, advanced depending on the design requirements in indoor to provide you better equipment.

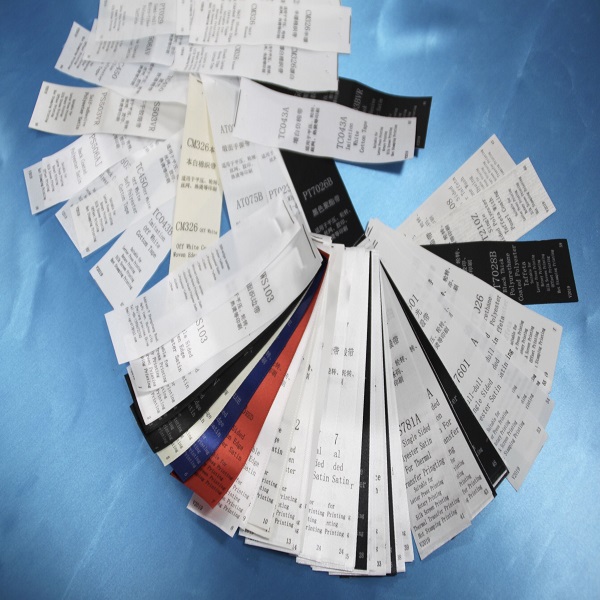

Product detail pictures:

Related Product Guide:

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for China Cheap price Intrared Label Drying Machine - High Speed Rotary Press – VTEX GROUP , The product will supply to all over the world, such as: Norway, belarus, panama, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing products, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.